Operation & Maintenance (O&M)

What determines the final generation output of a renewable energy power plant is O&M.

For renewable energy power plants located in natural environments to continue stable operation for a long duration, proper O&M is essential to prevent breakdowns and to respond quickly to malfunctions.

JUWI Shizen Energy Operation has many experienced professionals who have worked in various fields of power plant operation in Japan and around the world.

Our 365-day monitoring support system ensures stable operation of power plants.

Basic menu

Periodic inspection

To maintain the power plant’s potential

Solar power generation facilities with an output of 50 kW or more has inspection obligations. Our O&M services include periodic inspections as a standard service. We conduct inspections with customized content for each power plant and ensure smooth reporting. Approximately 70%* of the solar power plants we manage are extra high-voltage solar power plants. You can also rely on us to perform annual statutory inspections, including private transmission lines.

* capacity basedEmergency inspection

Minimize power generation loss in case of sudden problems

We monitor the operational status of our power plants 365 days a year. In the event of a natural disaster or power plant problem, we gather information, confirm safety, and then rush to the site to conduct a visual inspection. In the event of a power plant outage, we will respond quickly to minimize the duration of the outage.

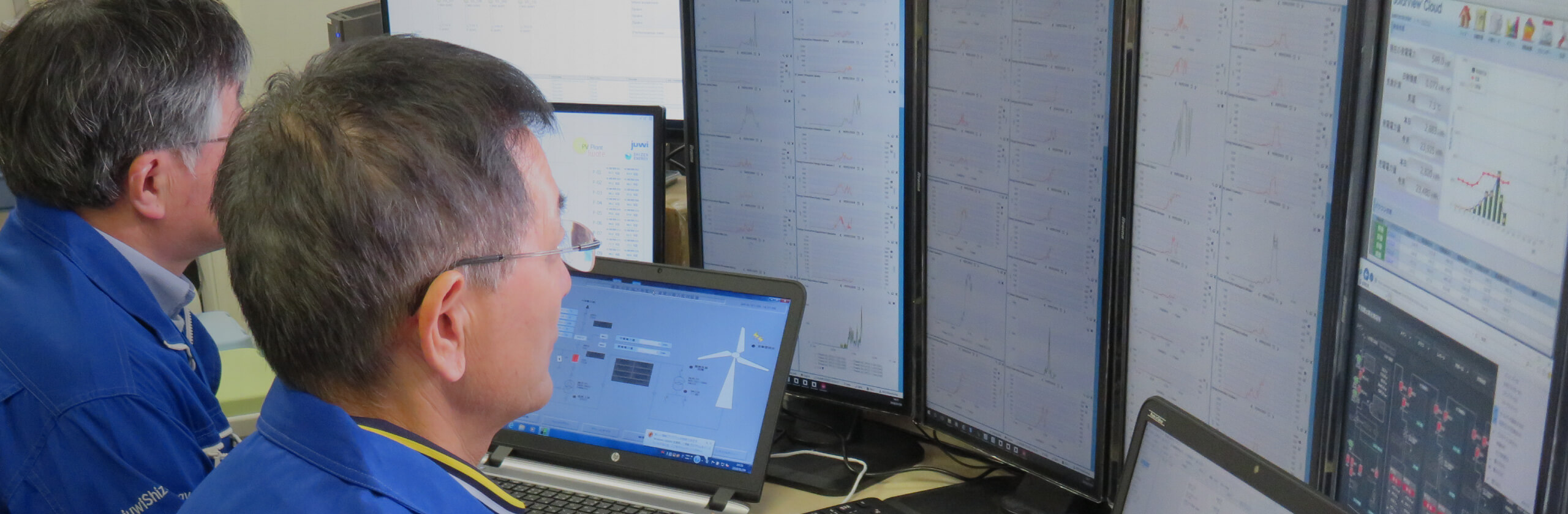

Monitoring

Monitoring from 6 locations (domestic/overseas) 365 days a year

We have 6 domestic and overseas locations (Iwate, Sendai, Tokyo, Hyogo, Fukuoka, India) monitoring each string 365 days a year. Prompt detection of abnormalities leads to appropriate assessments of power generation. Monitoring data is also included in monthly reports provided to our customers. The report includes not only the amount of solar radiation and power generation, but also the daily Performance Ratio (PR). This information is useful for understanding the operating status of the power plant.

Weed control

We can take care of your troublesome weeds

In some cases, customers make their own arrangements for weeding at solar power plants, however for the power plants we manage, we propose and implement periodic weeding. If many weeds continue to overgrow from spring to summer, it can lead to complaints from the surrounding community and also be an obstacle to periodic inspections and emergency response. Our weeding specialists will work carefully and safely.

Snow removal

Planned and emergency snow removal

In areas with heavy snowfall, snow not only covers solar panels and reduces power generation efficiency, but the weight of the accumulated snow can also put a strain on panels, cables, and mounts. In addition, the entrances to power plants and pathways for management can be obstructed by snow, which in some cases hinders inspections and handling of problems when they occur. We have extensive experience in snow removal work, and our regional network enables us to dispatch work quickly. We also monitor snow conditions daily and respond at the appropriate time for each power plant.

Maintenance

Speedy repair in case of breakdowns

Power plant equipment may fail for various reasons, including malfunctions, deterioration over time, or breakdowns due to natural disasters. When we discover a malfunction, we will propose the best repair method. In addition, our experience with domestic and overseas suppliers enables us to quickly negotiate procurement and warrantees.

Module cleaning

Above: before module cleaning

Below: after module cleaningCleaning to restore power generation efficiency

Due to the angle of installation and rainwater, dirt on the surface of solar panels was once said to be maintenance-free. However, depending on the environment in which the panels are installed, a wide variety of contaminants can adhere and accumulate, leading to a gradual decline in power generation. We use appropriate cleaning methods for each power plant to improve power generation efficiency. We also measure power generation data before and after cleaning, to verify the effects.

Contact

If you have any questions about our services, please contact us using the inquiry form below.