Power Plant Diagnostic Service

Do you have any concerns that your renewable energy power plant is not performing as well as expected or not as profitable? Or that your power plant is experiencing frequent power failure?

Fault detection of solar panels can be difficult, and a delay in repair can lead to more loss of electricity sales.

Based on our experience in O&M of many power plants, we offer a “Power Plant Diagnostic Service” to identify problems that are difficult to detect and in need of preventive repairs.

Would you like your power plant to have a “health checkup” to grasp its current status and draw out its full potential?

This service can also be used as a third-party evaluation before handover, when warranty is about to expire, or when purchasing a second-hand power plant.

Overview of Power Plant Diagnostic Service

On-site survey and inspection

Our specialist will visit your power plant to conduct inspection and measurements from an expert perspective

Data analysis

We will diagnose and evaluate the performance and soundness of your power plant from a third-party standpoint, based on the data obtained from the on-site survey and inspection and documents such as the design of the power plant.

Reporting

We will submit a report summarizing the inspection results. If any defects are found, we will also identify the cause and provide advice on how to repair them.

Basic courses

Two basic courses are available, according to your budget and purpose. We can also provide any combination of inspections or just one inspection, so please feel free to consult with us.

| Main inspection items | Light Course | Full Spec Course |

|---|---|---|

| 1. Infrared thermographic inspection (using a drone) | ◎ | ◎ |

| 2. Output characteristic inspection (IV curve measurement) | ◯ | ◎ |

| 3. Junction box and mounting structure inspection | ◯ | ◎ |

| 4. Soil and drainage facility inspection | ◎ | |

| 5. Insulation resistance inspection | ◎ | |

| 6. String disconnection inspection | ◎ | |

| 7. Electroluminescence (EL) inspection | ◎ | |

| 8. Visual inspection of other major equipment | ◯ | ◎ |

◎ Performed by all or by array ◯ Sampling inspection

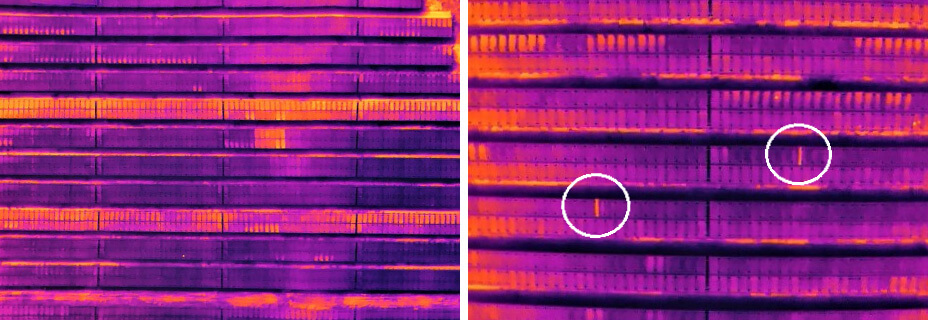

Infrared thermographic inspection

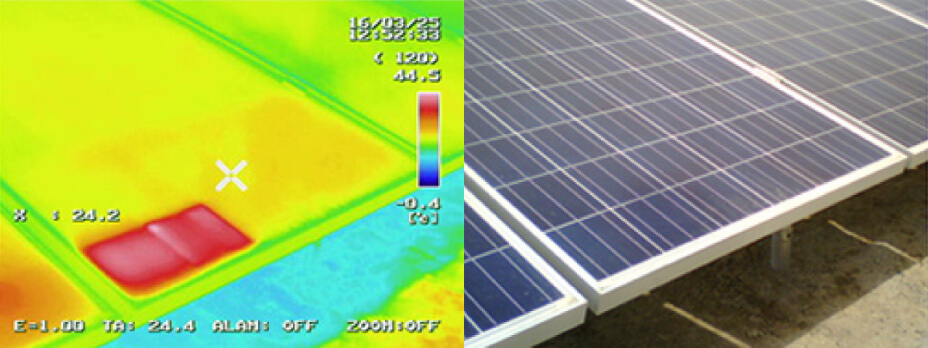

This inspection method uses infrared light to detect abnormal overheating areas called hot spots, which are difficult to detect visually.

It is suitable for detecting faults such as disconnections inside strings and modules, or broken surface glass. We inspect all panels using a drone to ensure that nothing is missed.

The orange heated part indicates a power outage due to disconnection.

A panel with hot spot in the absence of shading* may be replaceable by manufacturer without charge Output characteristic inspection (IV curve measurement)

For every string, we measure the output characteristics of the panels, called the IV curve. Based on the results, we evaluate and analyze whether the power plant is generating power as designed. We also identify panels with abnormalities and analyze the causes.

String disconnection inspection

Specialized equipment is used to find disconnections inside the panel called string breaks or cluster breaks.

Insulation resistance inspection

If the insulation performance deteriorates, a leakage condition may occur, leading to a prolonged shutdown of the power plant.

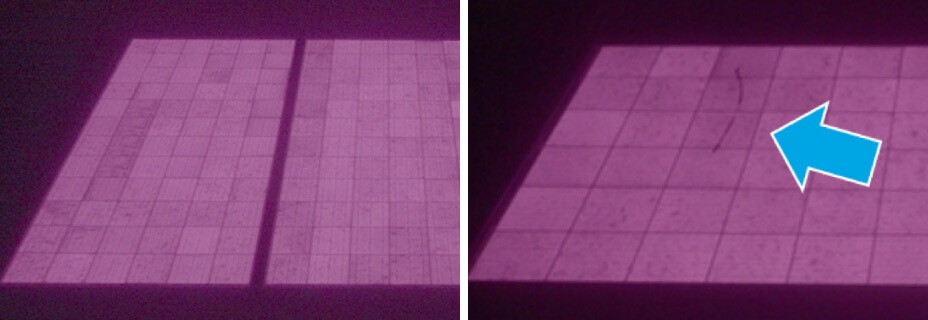

By measuring insulation resistance, problematic areas can be identified at an early stage and countermeasures can be taken.Electroluminescence (EL) inspection

EL inspection by a drone equipped with a special camera This method allows us to see faults like an X-ray photograph where internal conditions are difficult to detect visually or with infrared inspection. Panels with reduced output due to cell cracks or PID (Potential Induced Degradation) phenomena can be detected.

(left) Normal panel

(right) Scratches on the back of the module has extended to the interior

Completion Inspection Service

We carry out the completion inspection on behalf of the customer at the time of handover of the power plant. Our engineers with specialized skills evaluate whether the plant has been constructed according to the design without any defects and point out any problems that may exist. We also provide advice on how to prevent problems from occurring in the operation and maintenance of the power plant, based on our extensive experience.

Inspection Content

- Power generation equipment inspection

- Inspect correct installation of solar panels, PCS, and junction boxes

- Construction quality inspection

- Height and angle of the solar panel mounts and the torque of the tightening bolts are measured to inspect whether the structure is correctly installed

- Other equipment inspections

- Inspection of sensors such as pyranometers, waterproofing treatment in various locations, and drainage facilities for power plant operation and trouble prevention

- Safety inspection

- Inspection of cable connections, grounding, and other safety-related elements and equipment for correct installation

- Statutory inspection

- Inspection for compliance with laws and regulations, including signs and fence height

- Inspection of completed construction documents

- Inspection of all the necessary completed construction documents such as designs, specifications, and construction records compiled together. (In general, we also collect information from the EPC company.)

*In addition to the above, inspections will also include items from the “Power Plant Diagnostic Service.”

We can customize this inspection service to suit your needs, so please feel free to contact us.

Examples of inspection

Panel tilt angle measurement

Bolt torque measurement

Check installation of module connectors

Check soil scouring conditions on site

Check waterproofing treatment of conduit pipes

Contact

If you have any questions about our services, please contact us using the inquiry form below.